These services ensure that each Minebea Intec system is installed, configured, tested, and validated before entering production.

Before any system enters live production, it must be correctly installed, configured, tested, and validated. Safeland’s Before Start-Up Services ensure that Minebea Intec weighing, inspection, and automation systems are fully prepared for safe, compliant, and efficient operation. These services minimise commissioning risks, prevent costly delays, and guarantee that systems perform exactly as specified from day one.

Our commissioning methodology follows international engineering and validation standards, supporting smooth transition from installation to production readiness.

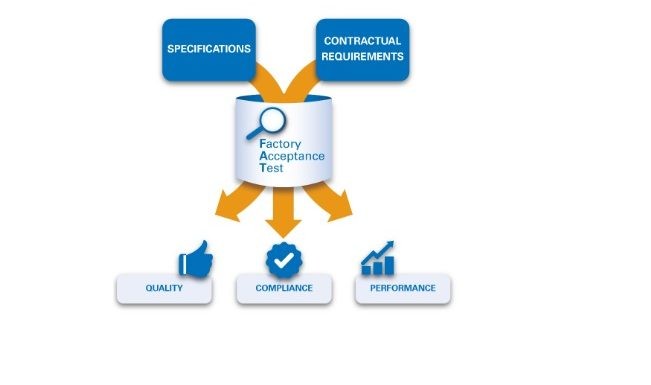

Factory Acceptance Testing is conducted at Minebea Intec’s manufacturing facility in Germany or an authorised partner site. This stage verifies system performance before shipment.

Site Acceptance Testing is performed at the customer’s facility after installation and integration.

For pharmaceutical, nutraceutical, and high-compliance environments, Safeland provides full IQ/OQ qualification services.

All installation and commissioning activities are carried out by certified Safeland engineers trained on Minebea Intec technologies.

Safeland maintains a comprehensive inventory of genuine Minebea Intec spare parts to ensure fast replacement and minimal downtime.

Value: Short lead times, guaranteed compatibility, full manufacturer warranty.

Accuracy is essential for quality assurance and regulatory compliance. Safeland provides calibration services in accordance with ISO/IEC 17025 guidelines through CALTEK or recognised laboratories.

© 2026 Safeland Technical Supplies .All Rights Reserved